- Mouldings[4]

- Other Construction Material Making Machinery[10]

- Brick Making Machinery[1]

- Moulds[1]

- Machinery Design Services[3]

- Crusher[4]

- Packaging Machinery[1]

- Bath & Shower Faucets[2]

- Machinery Processing Services[3]

- Pumps[7]

- Basin Faucets[6]

- Silicate[1]

- Curtain Walls[1]

- Tiles[1]

- Other Hardware[7]

- Contact Person : Mr. Liu William

- Company Name : Tangshan Hexiang Industrial Co., Ltd.

- Tel : 86-315-8381038

- Fax : 86-315-8381888

- Address : Hebei,tangshan,daxinzhuang town,fengnan district,

- Country/Region : China

- Zip : 063304

hi-pressure casting machine for washbaisn

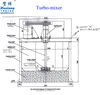

Hi-pressure Casting and Forming machine for wash basin

Model number: HX1032

Hexiang factory introduction:

Now, in Hexiang factory, we have a successful and hi-automatic lab testing line for sanitary ware, which includes Mould making, Hi-pressure casting machine for wash basin, tank, toilet and rim, drying chamber, cycle glazing line, shuttle kiln, packaging and testing machine. And now in our showing room, we have successfully finished the forming of base by hi-pressure.

Technical data:

1--Demoulding method: horizontal mould-opening + vacuum suction

2--Mould Matching Method: by hydraulic pressure

3--Pressure of mould matched: 310,000 N

4--Precision of mould match: ±0.25mm

5--Low-pressure of slip feeding: 0.02~0.05MPa

6--Hi-pressure of slip feeding: 0.8~1.0MPa

7--Pressure increased method of slip: by Hydraulic Pressure Machine

8-- Pressure of compressed air: ≥0.6MPa

9-- Pressure of water: 0.3MPa

10-- Quantity of mould: 8sets

11-- Total forming cycle: 16~35minutes/cycle

12-- Total Power: 12.05kW

13--Base taking method: By manual

14--Overall dimension : (L×W×H) 8800×2600×2700mm

Quality control:

Simple frame-structure application, and modular-design, which leads to the easy maintenance in short time.

Individual working station/modular-design, which avoid occurrence of group-stop caused by certain individual fault.

Top global-grade brand adopted in HPCM for a quality running, detail as following:

--For PLC component: the brand is SIMENS from Germany

--For Pneumatic components (except little ones such as plastic hose): 100% brand is SMC from Japan, including auxiliary solenoid valves

--For the motor auxiliary with hydraulic station, Brand of SIEMENS or ABB.

The machine tooling technique applied in the manufacture of HPCM, it cover 100% expects electrical control cabinet and pneumatic system.

--such as the very simple steel-frame of resin mould is manufactured as following produce-flow:

Assembly--Welding--Heat Treatment--Machine tooling--Finishing--Antirust Paint--Surface Paint

--For the pipe of hydraulic station, adoption of Acid cleaning/pickling for avoiding occurrence oxidation and rust; Passivation for have pipe more stronger for a better performance of pressure output.

Metal pipeline auxiliary with HPCM is made of Stainless Steel (304), for avoiding any occurrence of pollution.

Adoption of simple insert and pull out method in pipeline of demoulding, dewatering, vacuum and compressed, make operation and maintenance very easy.

Adoption of PLC with Touching Screen, and it is real easy operation just by inputting particular parameter. The slip feeding hose is ss304 bellows with meshwork so as to guarantee the stable performance of hos

Parts picture of machine-----

hi-pressure casting machine for washbaisn